Tailormade sustainable cooling solutions

Since 1938, we reinvent cooling and lead the way in creating ever more advanced, reliable and energy-efficient cooling solutions. Green Hydrogen production requires cooling solutions to be successful and BAC has the knowledge, experience and solutions to meet the specific needs for this production process.

Discover how BAC supports the world's first hydrogen plant in steel production!

Reliable system operation

- Being a global company, we have dedicated local sales engineers, backed up by subject matter experts to offer our customers tailormade cooling solutions. We learn about our customer challenges and goals and together we select the best cooling technology and design a system that operates at peak performance no matter the size of the project.

- The thermal performance of our cooling products are CTI-Eurovent certified. Our customers can rely on a reliable and energy saving operation of the cooling system.

- We have local service teams to maintain and keep our products operational in critical cooling processes.

Interested in our expertise?

Tom Bosmans is Business Development Manager and BAC's hydrogen expert.

Contact Tom, and you will get to know how BAC can assist you in your cooling demand for green hydrogen production.

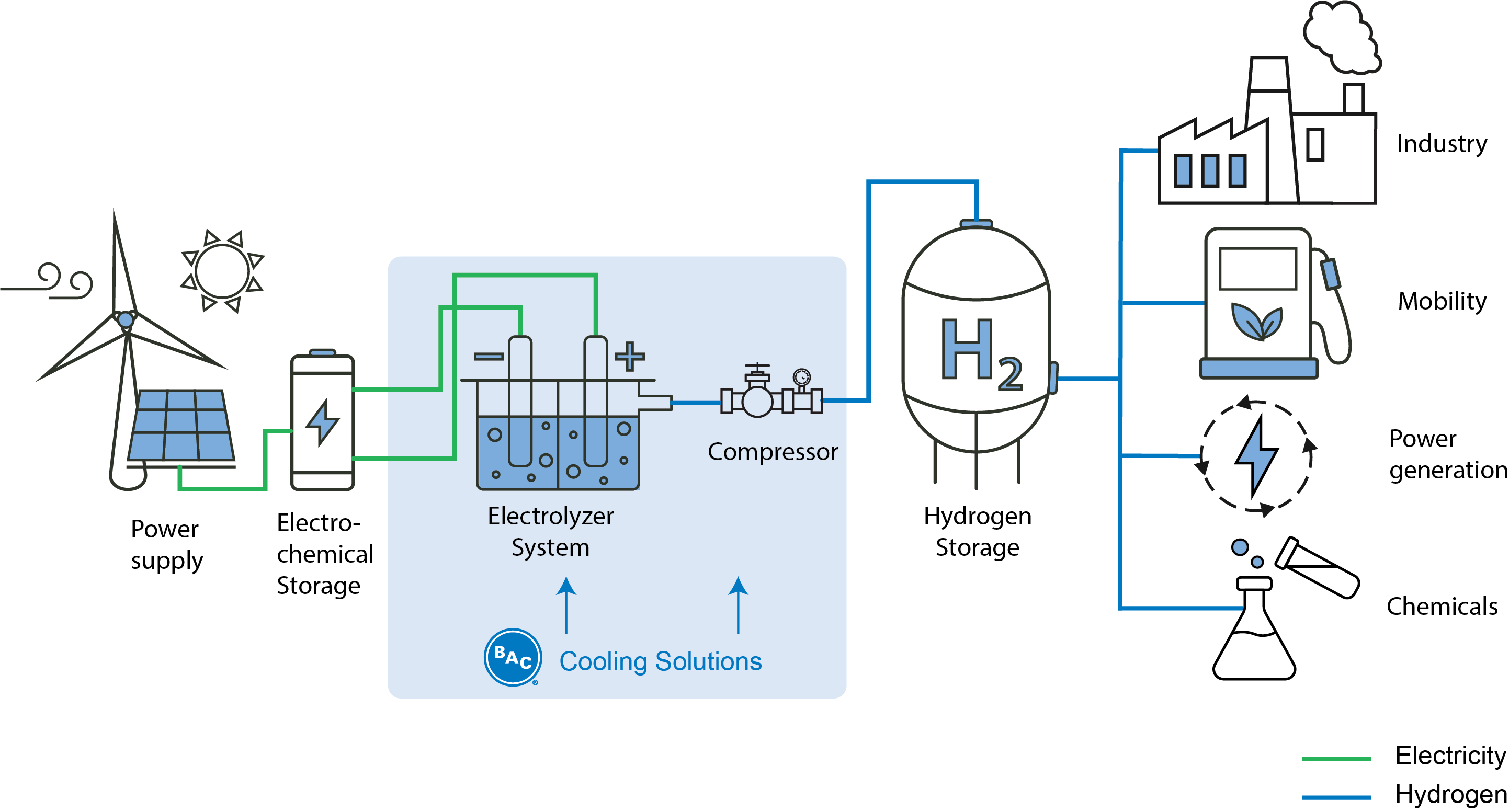

The role of cooling in production of Green Hydrogen

Green hydrogen is hydrogen produced from renewable sources of energy (wind, solar, hydropower) via electrolysis. The electrolysis process splits water molecules in hydrogen (H2) and oxygen (O2) as electricity passes through the water. The major advantage of this process is that there is no CO2 emission, therefore green hydrogen contributes to the reduction of global carbon emissions as opposed to hydrogen produced from non-renewable resources like natural gas.

The electrolysis process requires a significant amount of energy. A part of this energy is lost as heat. The amount of heat released can vary depending on the electrolyzer design. The capacity of an electrolyzer is expressed in MWe (megawatts of electricity input). During the electrolysis process, the heat losses will be approx. 25% to 35% of the electricity input and this heat will need to be rejected to keep the stack within a desired temperature range.

As an example, a 100MW(e) electrolyzer, releases approx. 30 MW heat and therefore the same amount of cooling will be required. Further downstream, there is also heat rejection required for the compression of the produced hydrogen. Electrolyzer and compressors can be cooled separately for small installations while for large scale installations, cooling can be combined via a central cooling system.

BAC's cooling solutions

We have a very extensive cooling product range. From evaporative open and closed circuit cooling towers, hybrid, adiabatic and dry cooling systems, whatever the application or the challenge, we have the knowledge in house to select the best product that meets your cooling needs.

The most suitable cooling technology is often determined by the project location and the availability and cost of water and/or electricity.

Open cooling towers

One way to provide the cooling is by means of an evaporative open cooling tower. Warm process water enters at the top of the cooling tower, flows over a heat transfer media (fill) and gets in contact with cold air. A part of the process water evaporates which removes the heat from the water. Cooling towers have multiple advantages over other cooling technologies:

- Extremely energy efficient,

- Compact footprint

- Lowest process temperatures because they can achieve a low approach (2-4°C).

Closed circuit cooling towers

If you want to isolate the process fluid from the outside air, you can use a closed circuit cooling tower. In this case there is no contact between the air and fluid being cooled.There are 2 separate circuits: the hot process fluid flows through a coil bundle and a second spray water system wets the coil bundle. The process water that flows through the coil stays clean and free from contamination. Benefits are:

- Smaller volume of spray water to treat less maintenance is required.

- No contamination of the process fluid

The coil bundle makes however this type of unit more expensive than an open cooling tower.

Adiabatic coolers

If there is not enough water available at the site location, adiabatic cooling can be the optimal solution. An adiabatic coolers is a dry cooler equipped with an adiabatic pre-cooler section. Before the air is drawn through the high density finned coil, it is pre-cooled adiabatically as it passes through an adiabtic pad where water is evaporated in the air. The air that enters the adiabatic pad is cooled to a depressed dry bulb temperature which is almost the wet bulb temperature. The dry finned coil will see cooler air which results in lower process temperatures. This type of coolers uses only water for a short amount of time during the year and is preferably used in regions with a low relative humidity. Benefits are:

- +/-90-95% water savings compared to an evaporative cooler.

- no water treatment

Interested in our expertise?

Tom Bosmans is Business Development Manager and BAC's hydrogen expert.

Contact Tom, and you will get to know how BAC can assist you in your cooling demand for green hydrogen production.